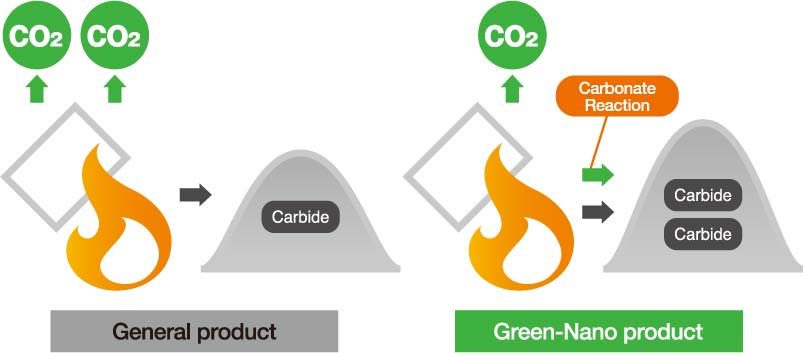

that significantly reduces CO₂ emissions during combustion

by adding only a small amount to ordinary plastics.

The design, materials and production facilities can remain the same at the time of introduction so there is almost no labor or initial cost. Since only a small amount of Greeen nano is added, it is said to be one of the most environmentally friendly plastics that can be "eco-friendly" at a low cost.

solvent dispersion / water dispersion, etc.

Functional masterbatches for uniform dispersion of carbonization accelerators.

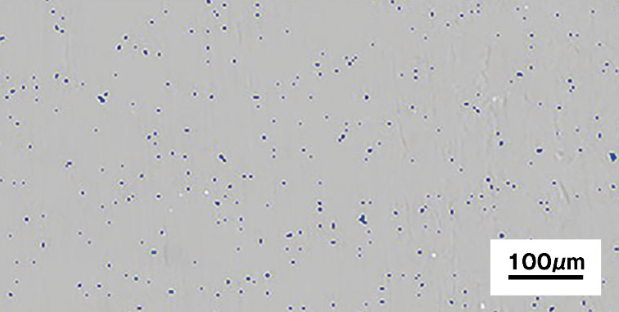

Moderately dispersed and arranged carbonization accelerators.

Carbonization Accelerator

●Carbides are produced in greater quantities than usual.

●As carbon is trapped in the residue (ash), the amount of CO₂ released into the atmosphere is reduced.

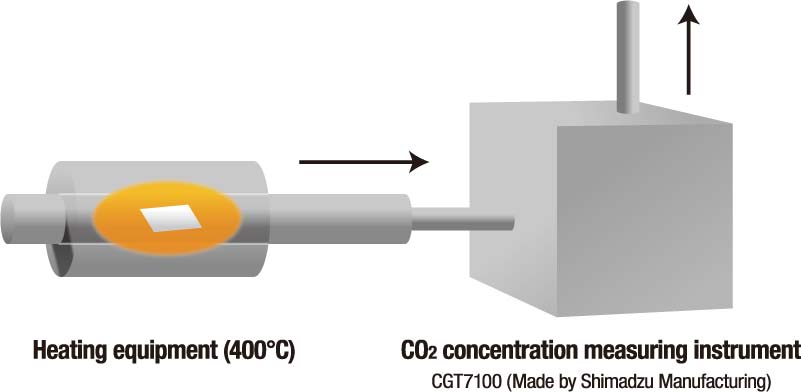

■ Specimen Size (per measurement)

Size: about 2 to 5 cm square / Weight: up to ~1g

■ Measurement time: time from start of measurement until CO₂ reaches 0 vol%.

※However, in stoker furnaces, which account for nearly 80% of waste incineration facilities in Japan, chemical reactions due to thermal decomposition have already occurred in the drying and preheating section (approximately 200°C to 500°C) of the stoker furnaces and the typical heating temperature for combustion tests is set at 400°C as a typical temperature at which resinous materials react violently in the combustion test.

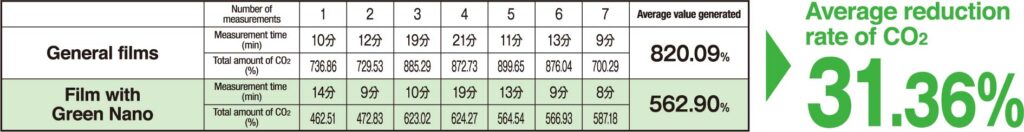

■Combustion measurement results of PE film for garbage bags (measured by Aitos Machinery Co., Ltd.)

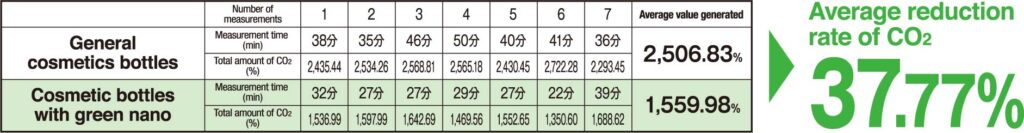

■Combustion measurement results of cosmetics PP bottles (measured by Aitos Machinery Co., Ltd.)

※CO₂GAS amount converted as per unit weight of test piece

※Average occurrence (n5 average value: maximum and minimum values excluded)

※The above data is for reference only. The above figures may not be achieved even with the same base material.Reduction rates vary depending on product composition and blending ratio.

*1: Changes in transparency and strength of plastic are the opinions of individual customers that are not guaranteed.

Before using the product, please be sure to make a sample to check the compatibility with the actual product. For more information, please contact the department in charge.