Kaminano, Kaminano Light and Kaminano Board were introduced in Senken Newspaper.

「Senken Plus https://senken.co.jp/」

TENTAC strengthen Sales of Paper Materials

Tentac to capture demand by Switching to "Kaminano" Series

TENTAC, a mainstay brand tag and packaging company, is focusing on the development and sales of paper materials.As fashion and retail companies accelerate the trend away from plastics, the company is expanding its selection of paper materials according to function, cost and texture, capturing the demand to switch from plastic to paper.

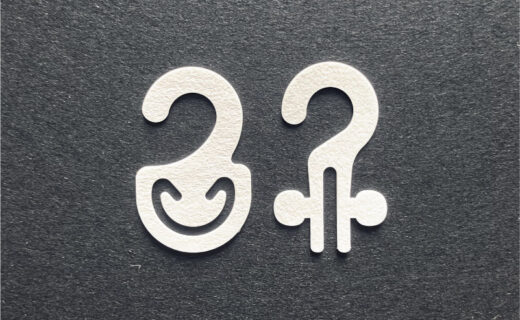

Starting this year, the company is promoting a series of paper hooks, keepers and other materials as the "Kaminano" brand.This year they anticipate sales of 200 million yen with the Kaminano series and the policy is to "compete globally as an alternative material to plastic".(Junki Hashimoto, the head of the company).

In addition to Kaminano, which has the same strength and elasticity as plastic and is mainly used for shirts, the company offers Kaminano Light, which has resilience inferior to that of Kaminano but is easy to switch from plastic due to its cost advantage and is suitable for hooks and hangers, also Kaminano Board, which is made from recycled kraft paper such as rice bags and has a textured appearance.

The introduction of Kaminano was preceded by major companies for a variety of applications, including shirts and innerwear for a major GMS (general merchandise store), handkerchiefs and towels for furniture and interior design and innerwear and legwear for a major global SPA (manufacturing and retailing company) for Kaminano Board. Adoption by small and medium-sized fashion companies and other industries is also gaining momentum.

Kaminano is a special reinforced paper made from 100% natural cellulose fiber, which is once broken down to the nano-level called cellulose nanofiber and then re-agglomerated and bound together.It is strengthened by unconventional methods such as surface coating and mixing in reinforcing agents and is also highly biodegradable.As an alternative material to plastic, it is "stronger than plastic" for the same thickness.

It is being developed jointly with a major paper manufacturer and "can be sold almost exclusively."Cost advantages are achieved by bulk purchasing of materials and integrated production in Japan and China."Until now, cost has often been a barrier switching from plastic to paper" but this has been eliminated.The company has established a sales network at its domestic and international locations.

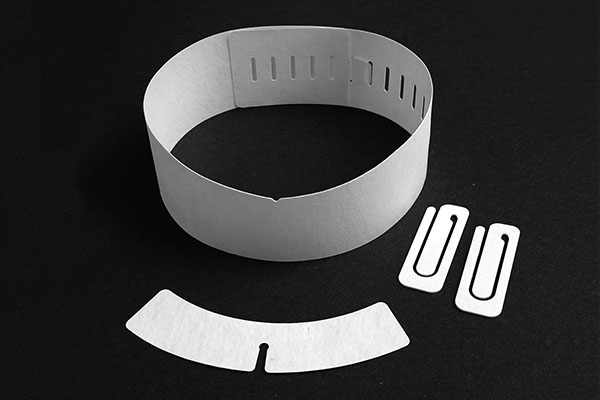

Adopted for popular PB Shirts at Ito Yokado

Ito Yokado switched materials such as color keepers and pins to "Kaminano" in its "Super Form-stable Shirts" line of PB shirts, which were revamped this spring.This business shirt is a popular product that has sold a total of 3.3 million shirts since its launch in 2015.The adoption of Kaminano is expected to reduce the number of plastic bottles by 200,000 per year.Sales exceeded the expectation, supported by the use of environmentally friendly materials in point-of-purchase (POP) advertisements and other means.

Making shirt materials sustainable was a major challenge, for the company which has been strengthening the development of environmentally friendly products.While searching for an alternative material to plastic, the company decided to introduce Kaminano, based on the premise that it would be strong enough to withstand delivery and allow the shirt collars to be displayed neatly in stores.

The business shirts are produced in Myanmar and brought to Japan by sea."The strength of the product to keep its shape while it is on board for about a month was a deciding factor in our decision to use Kaminano." (Kazuya Kato, Ito Yokado Clothing & Sundries Department's Merchandiser)As a result of repeated trials with both shipping and land transportation in Japan, the company was able to implement the product "it is less prone to lose its shape than when plastic materials were used".