Tentac's new product "hazai nano" was introduced by Senken Shimbun.

"Senken Plus https://senken.co.jp/"

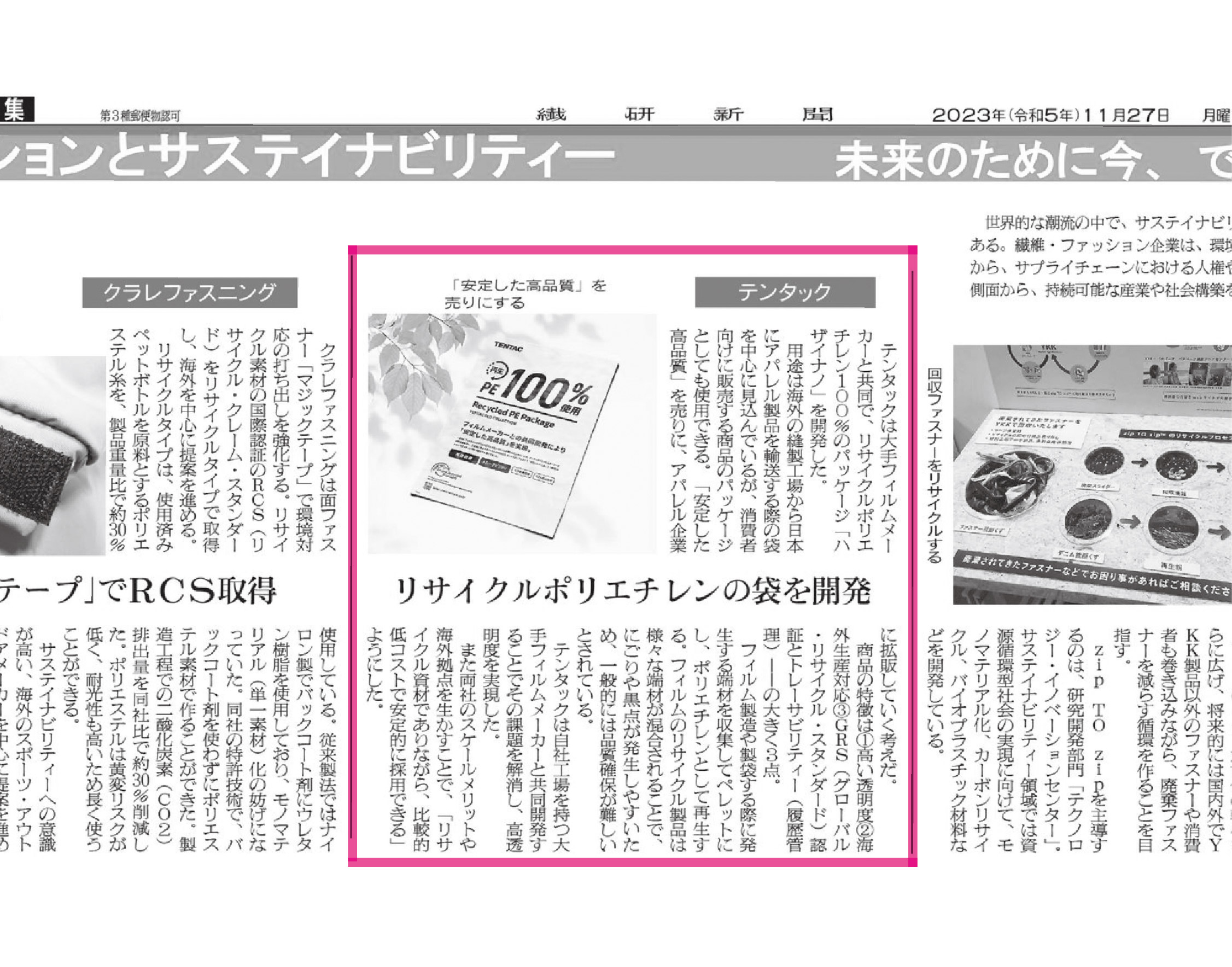

【Fashion and Sustainability】TENTAC developed Recycled Polyethylene Bags

TENTAC has developed a 100% recycled polyethylene package called "hazai nano", in collaboration with a major film manufacturer.

The bags are expected to be used primarily as bags for transporting apparel products from overseas garment factories to Japan, but they can also be used as packaging for products sold to customers.The company intends to expand sales to apparel companies by selling "Stable and High Quality" products.

The products are characterized by three main features: (1) High Transparency, (2) Overseas Production Compatibility and (3) GRS (Global Recycling Standard) Certification and Traceability (history management).

Scrap materials generated during film production and bag making are collected then made into pellets, which are recycled as polyethylene.It is generally considered difficult to ensure the quality of recycled film products because they are prone to smudging and black spots due to the mixture of various end materials.

TENTAC solved this problem and achieved high transparency by jointly developing the film with a major film manufacturer that has its own factory.

In addition, by taking advantage of the scale merits of both companies and their overseas bases, the company was able to "stably employ recycled materials at a relatively low cost".

Selling "Stable and High Quality"